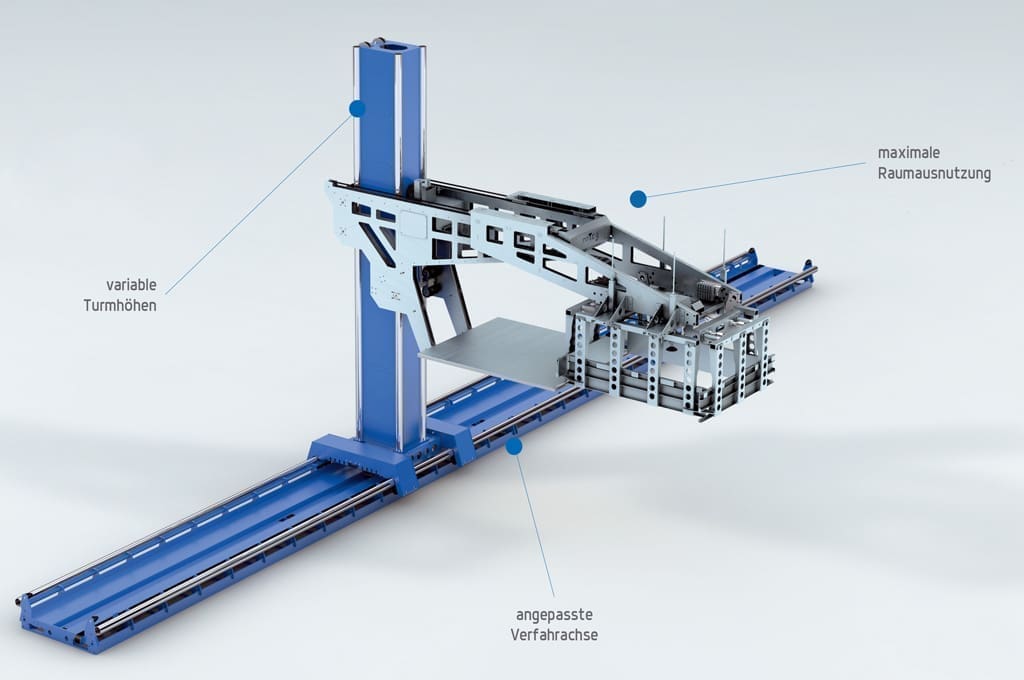

Depallatized in the smallest of spaces:

The three axis from the robot are driven by a maintenance free servo motor. Thanks to the robust construction and the use of simple kinematics the operating costs are reduced to a minimum.

Reliable layer gripper:

A reliable gripping system is essential for picking up entire layers. The layer gripper designed and manufactured by roTeg encloses the top package layer and pulls it onto the sheet metal positioned behind the pallet. The complete layer is pushed back on the discharge table. Meanwhile the intermediate layer, still lying on the packages, is lifted and stored separately.

To enlarge the picture

please click on the illustration.

Depallatize in the narrowest space: Our compact roTeg depallatize robot I.

Concerning functionality and efficiency the roTeg depallatizing robot I sets new standards in robot controlled depallatizing. The use of low maintnenace components were very important in the development of the compactly built robot system.